When it comes to transporting heavy and oversized equipment, guessing is not an option; the right

lowbed trailer specifications can be the difference between a smooth delivery and a very expensive problem on the highway.

From massive excavators to industrial transformers, every load comes with strict limits on height, weight, and axle pressure. That’s why understanding lowbed trailer dimensions, deck height, load capacity, and legal limits isn’t just for engineers; it’s essential knowledge for fleet managers, logistics planners, and construction companies that move serious machinery.

In this guide, we’ll break down the most important technical details of lowbed trailers in plain language. You’ll learn how specifications affect safety, compliance, and real-world performance, and how to choose the right configuration for different types of heavy cargo.

If you’re upgrading your fleet or planning your next transport job, this breakdown will help you make smarter, regulation-friendly decisions without needing a calculator and three cups of coffee.

What Do Lowbed Trailer Specifications Actually Mean?

The term

“lowbed trailer specifications” sounds technical, and yes, there are numbers involved. Still, at its core, it simply refers to the physical and mechanical limits that define what a trailer can safely and legally transport.

These specifications are not just manufacturer details for a brochure. They directly affect route planning, permit requirements, loading methods, and long-term equipment safety.

Here are the main categories that matter:

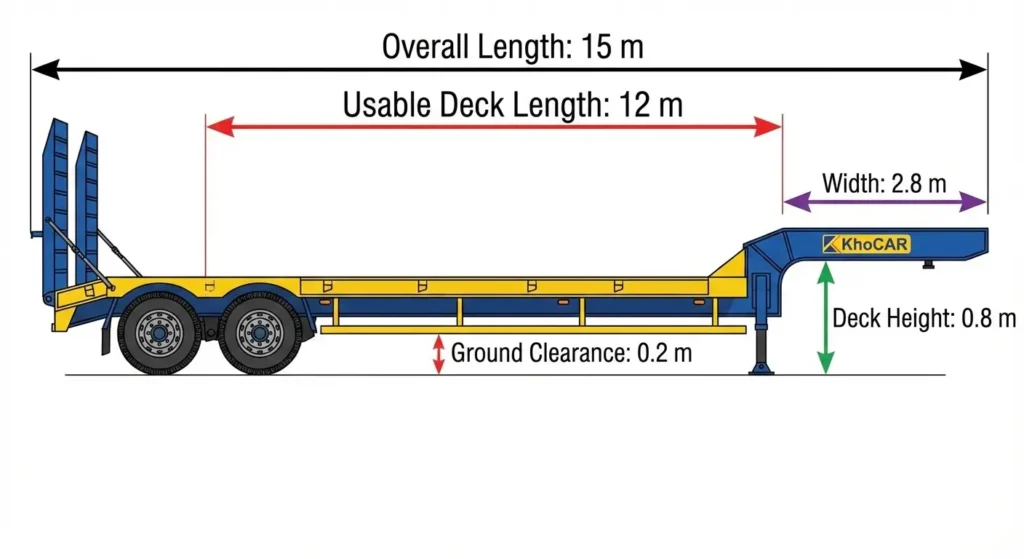

Dimensions

This includes the overall length and width of the trailer, as well as the usable deck length where the cargo sits. Dimensions determine whether your load fits physically on the trailer and whether the combined vehicle stays within legal road limits.

Deck Height

Deck height is the distance from the ground to the trailer deck. A lower deck allows taller equipment to stay within legal height limits during transport, which is one of the biggest advantages of using a lowbed trailer in the first place.

Load and Weight Capacity

These terms describe how much weight the trailer can safely carry. Load capacity usually refers to the maximum payload, while total weight capacity also includes the weight of the trailer itself. Exceeding either can damage equipment, reduce braking performance, and trigger regulatory penalties.

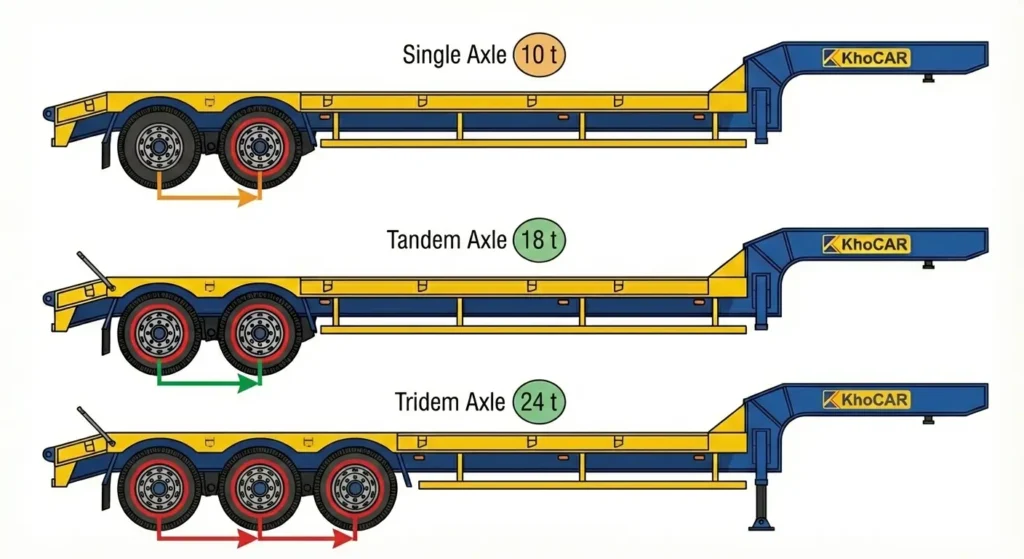

Axle Configuration and Axle Load

The number of axles and how weight is distributed across them determines how much pressure is placed on the road surface. Many transport regulations are based on axle load limits, not just total vehicle weight, which makes axle configuration a critical part of compliance.

Legal Height and Road Limits

Even if a trailer can physically carry a load, it still must comply with regional road regulations. Legal height limits, width restrictions, and axle load rules all influence whether permits are required and which routes are allowed.

Understanding these core specification categories makes it much easier to evaluate different lowbed trailer models and choose the right setup for specific cargo types, which brings us to the first set of hard numbers: dimensions.

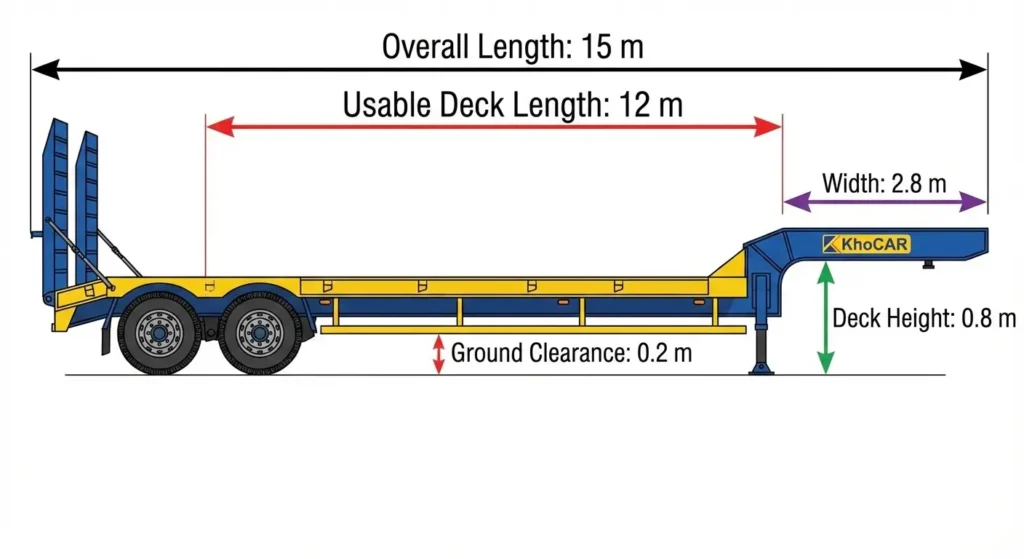

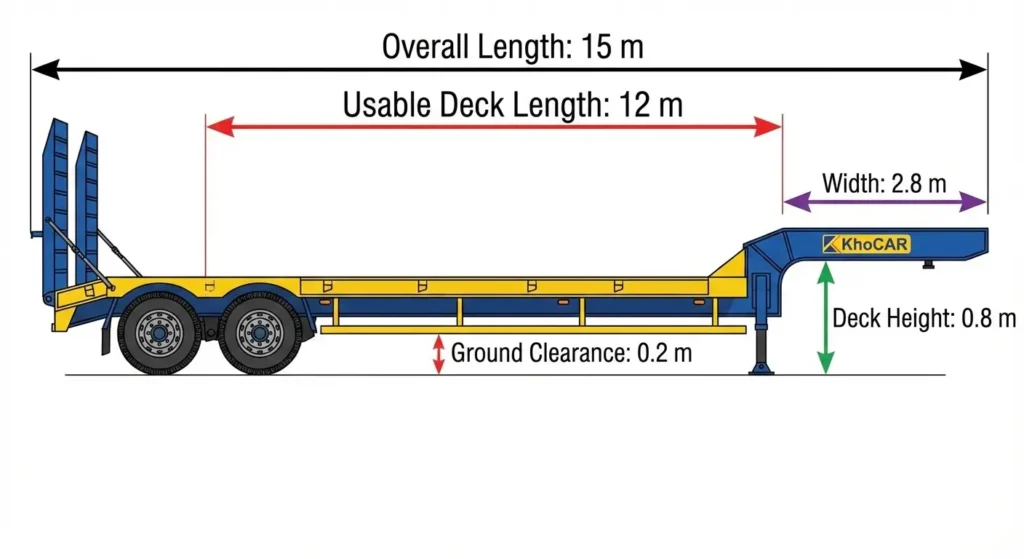

Lowbed Trailer Dimensions: Length, Width & Deck Height Explained

Lowbed trailer dimensions play a huge role in determining what you can transport, which routes you can take, and whether you’ll need special permits. While exact measurements vary by manufacturer and configuration, most lowbed trailers fall within well-established industry ranges.

Understanding these standard dimensions helps logistics teams quickly assess whether a specific machine or cargo type can be transported safely and legally.

Key Lowbed Trailer Dimension Ranges

| Specification |

Typical Range |

Why It Matters |

| Overall Trailer Length |

12 m – 18 m (40 – 60 ft) |

Affects maneuverability and legal road limits |

| Useable Deck Length |

8 m – 12 m (26 – 40 ft) |

Determines how much cargo fits on the deck |

| Trailer Width |

2.5 m – 3.0 m (8.2 – 10 ft) |

Standard road width is usually ~2.5 m; wider loads may need permits |

| Deck Height |

0.6 m – 1.0 m (24 – 40 in) |

Lower deck = more legal height available for tall cargo |

| Ground Clearance |

150 – 300 mm |

Impacts loading ramps and uneven terrain performance |

Why is deck height critical?

If the legal road height limit is about

4.0 – 4.5 m in many regions, every centimeter saved on deck height can be used for taller equipment, meaning fewer permits, fewer escorts, and fewer headaches.

Standard Width vs. Over-Width Transport

Most highways are designed for vehicles up to

2.5 meters wide. Lowbed trailers built within this width can usually operate without special width permits (depending on the country and cargo).

However:

- Wider lowbed trailers allow more stability for heavy machinery

- But they often require oversize load permits and route approvals

So, width becomes a trade-off between

capacity and regulatory complexity.

Extendable Lowbed Trailers and Variable Dimensions

Some lowbed trailers are

extendable, allowing the deck length to increase for long cargo such as wind turbine components or steel structures.

Typical extension ranges:

- Base deck: 8–10 m

- Extended deck: up to 15–20 m or more

This flexibility is useful, but longer trailers:

- Increase turning radius

- May require special turning route planning

- Often triggers additional permit requirements

How Dimensions Affect Compliance and Safety

Dimensions don’t exist in isolation. They directly influence:

- Legal transport height

- Bridge and tunnel clearance

- Turning radius on city roads

- Load stability during braking and cornering

That’s why professional operators always evaluate

deck height, width, and length together, not separately.

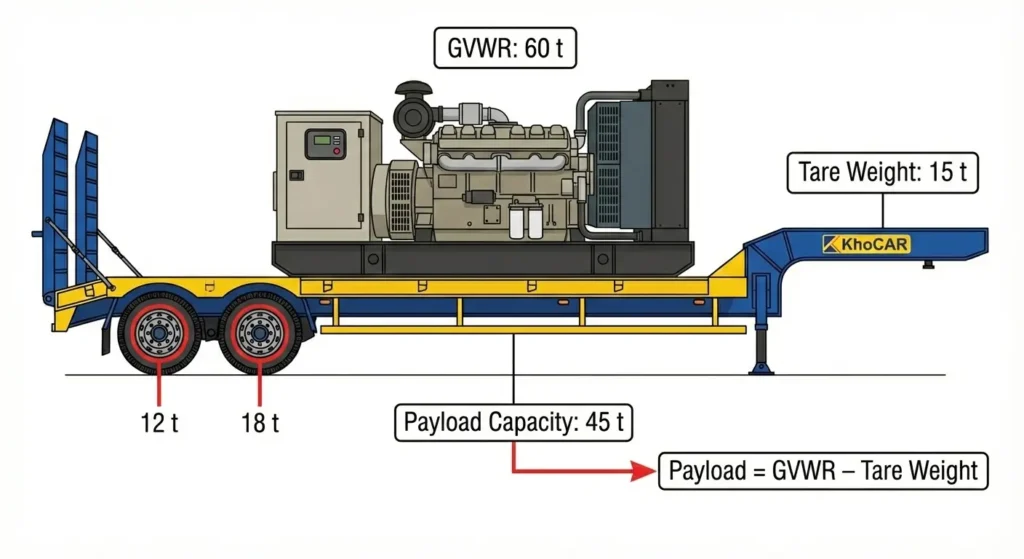

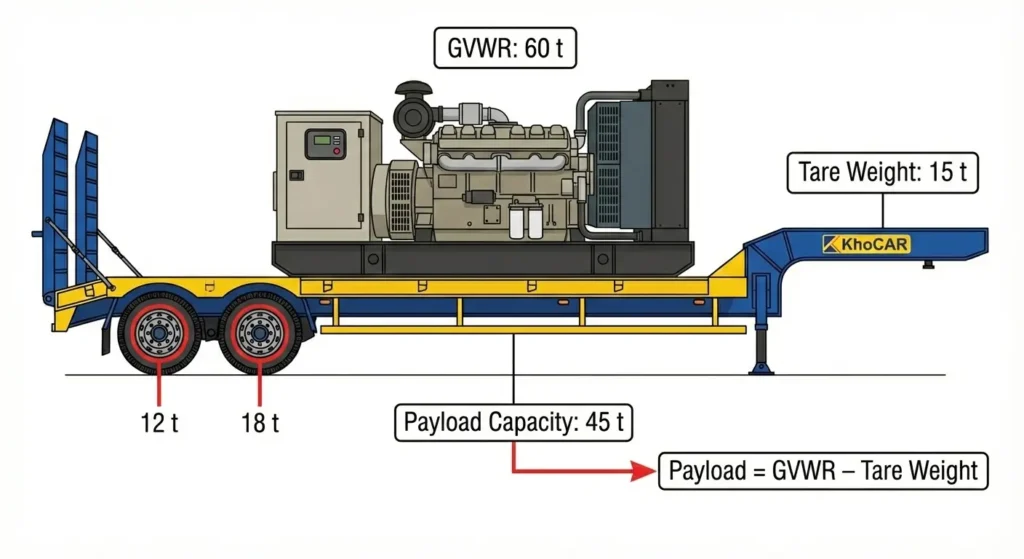

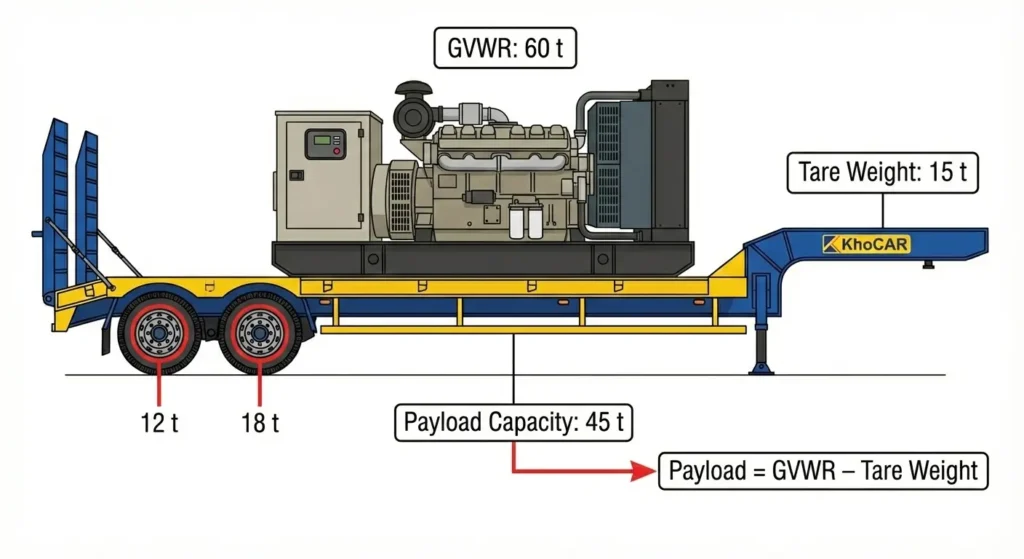

Lowbed Trailer Load Capacity & Weight Capacity: What Can It Really Carry?

When people ask about lowbed trailer capacity, they usually mean one thing:

How heavy can my cargo be?

But in technical terms, there are

two different weight limits you must understand to avoid costly (and very illegal) mistakes.

Load Capacity vs. Weight Capacity (GVWR)

Let’s clear up the terminology first:

Load Capacity (Payload):

The maximum weight of the cargo the trailer can carry.

Gross Vehicle Weight Rating (GVWR) / Total Weight Capacity:

The maximum total weight of the fully loaded trailer, including:

- Trailer weight (tare)

- Cargo weight

- Fuel, chains, and accessories

Formula you can actually use:

Payload Capacity = GVWR – Trailer Tare Weight

If your trailer has a GVWR of 80,000 kg and the trailer itself weighs 20,000 kg, your maximum payload is

60,000 kg.

Typical Lowbed Trailer Load Capacity Ranges

Actual capacity depends heavily on axle count, frame design, and suspension type, but most lowbed trailers fall into the following ranges:

| Trailer Type |

Typical Payload Capacity |

Common Use Cases |

| 2–3 Axle Lowbed |

20 – 40 tons |

Small excavators, generators |

| 4–5 Axle Lowbed |

40 – 70 tons |

Large construction equipment |

| 6+ Axle Heavy-Duty Lowbed |

70 – 120+ tons |

Transformers, mining equipment |

These ranges can increase with:

- Hydraulic suspension systems

- Reinforced frames

- Modular axle configurations

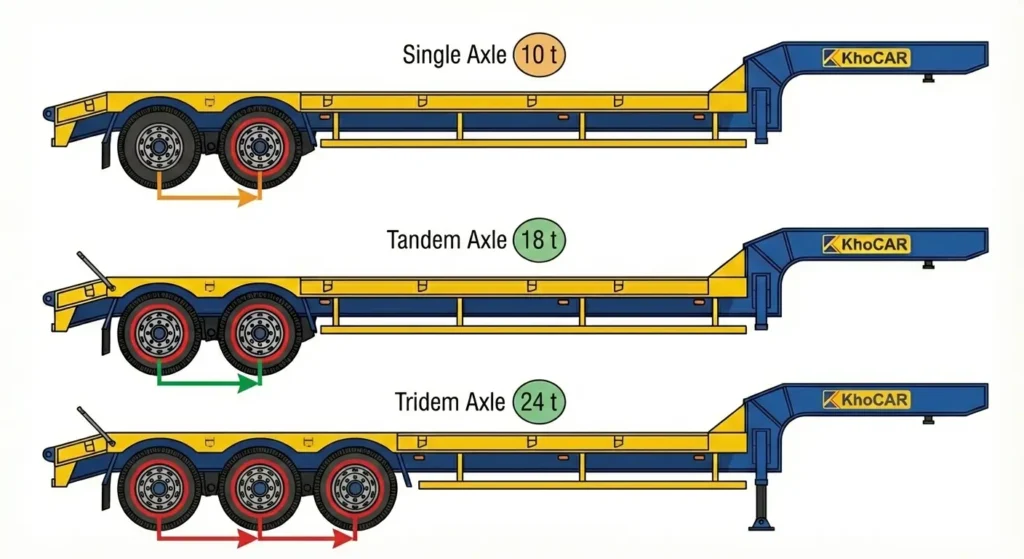

Why Axle Count Changes Everything

Adding axles doesn’t just increase total capacity; it reduces the

load per axle, which is what most road authorities actually regulate.

For example:

- A 60-ton load on 3 axles = 20 tons per axle

- The same load on 6 axles = 10 tons per axle

Lower axle load:

- Improves road compliance

- Reduces pavement damage

- Increases route options

This is why heavy-haul operators often prefer multi-axle lowbed trailers even when total capacity seems similar.

Weight Distribution Matters as Much as Total Weight

Even if your trailer is rated for the weight, poor load placement can still cause:

- Overloaded rear axles

- Reduced steering traction

- Uneven braking

- Higher tire and suspension wear

Best practice includes:

- Centering heavy equipment over multiple axles

- Checking axle group weights, not just total mass

- Using load plans for oversized machinery

In short, where the weight sits is just as important as how much it weighs.

Compliance Isn’t Optional (Sadly, Paperwork Always Wins)

Most regions enforce:

- Maximum gross vehicle weight

- Maximum axle load

- Bridge and road class restrictions

Exceeding legal limits can lead to:

- Fines

- Forced offloading

- Insurance issues

- Delayed projects (a contractor’s worst nightmare)

Which brings us neatly to the next critical topic…

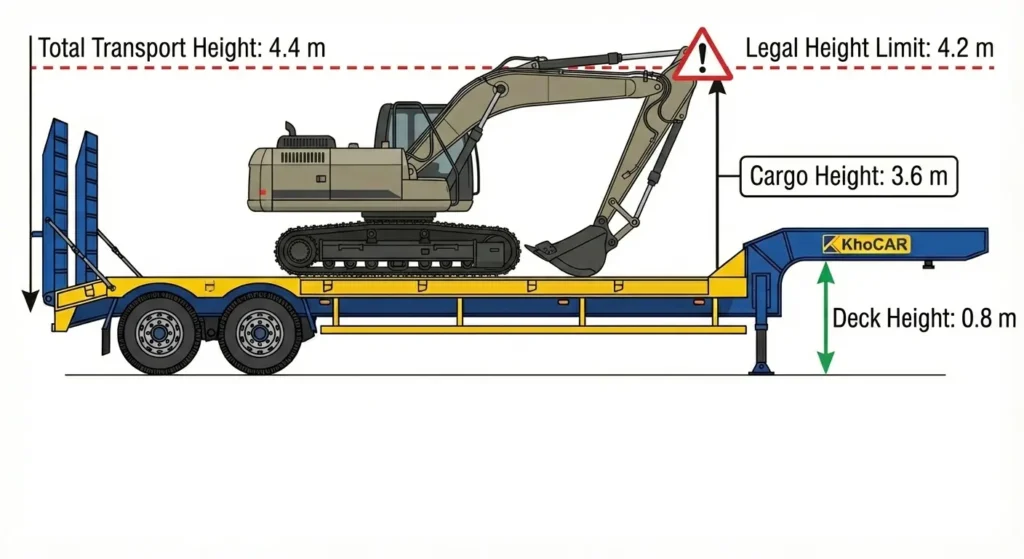

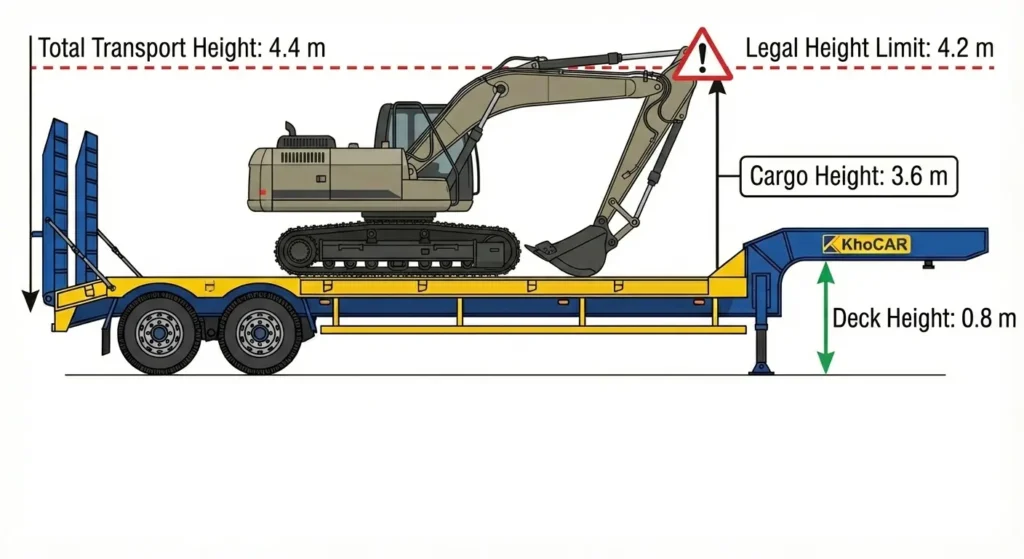

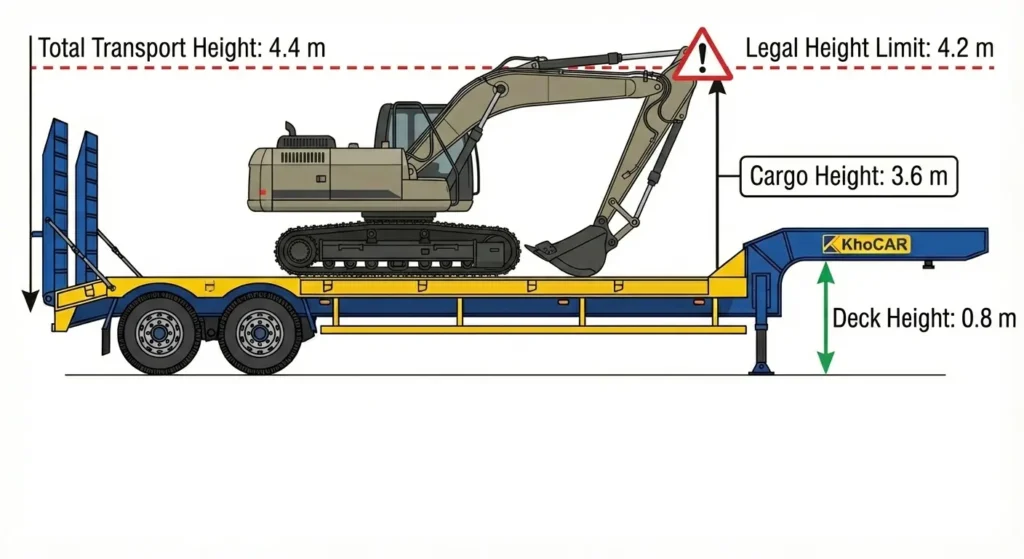

Lowbed Trailer Legal Height Limits and Total Transport Height

One of the biggest reasons lowbed trailers are used for heavy transport is simple:

they keep tall cargo within legal road height limits. But to do that properly, you need to understand how total transport height is calculated and what the legal limits typically allow.

What Is Total Transport Height?

Total transport height is the combined height of:

Deck Height + Cargo Height + Any Supporting Equipment

That includes:

- Blocking and supports

- Cradles or frames

- Even protective coverings in some cases

So, even small increases in deck height can push a load from “legal” to “oversized” very quickly.

Typical Legal Road Height Limits (General Industry Ranges)

While exact limits vary by country and region, most road authorities set legal height limits within these ranges:

| Region (Typical) |

Legal Height Limit |

| Many Countries (General) |

4.0 m – 4.5 m |

| Special Heavy Transport Routes |

Up to 5.0 m (with permits) |

| Urban Areas / Bridges |

Often lower than highway limits |

Always check local regulations before planning transport; bridge clearances can be much lower than national limits.

Why Deck Height Is the Secret Weapon

Lowbed trailer deck height usually ranges between

0.6 m and 1.0 m, which is significantly lower than that of standard flatbed trailers.

This means:

- Taller machines can stay under legal limits

- Fewer escort vehicles required

- Fewer route restrictions

- Lower permit costs

Example:

If the legal height is 4.2 m and your machine is 3.4 m tall:

- With 0.9 m deck height → Total height = 3 m (permit needed)

- With 0.7 m deck height → Total height = 1 m (often legal)

Two centimeters saved… thousands of dollars saved. Math has never been so satisfying.

When Permits Become Necessary

Even with low deck heights, permits may still be required if:

- Cargo exceeds legal height

- Width exceeds standard lane limits

- Axle load exceeds legal thresholds

- Bridge classifications are exceeded

Permit conditions may include:

- Restricted travel hours

- Police or pilot vehicle escorts

- Approved transport routes only

This is why choosing the

lowest practical deck height is often part of permit reduction strategies.

Height Isn’t Just About Law: It’s About Safety

Excessive height increases:

- Rollover risk

- Wind sensitivity

- Clearance hazards under bridges and cables

So, staying within limits isn’t just about avoiding fines; it’s about protecting equipment, drivers, and infrastructure.

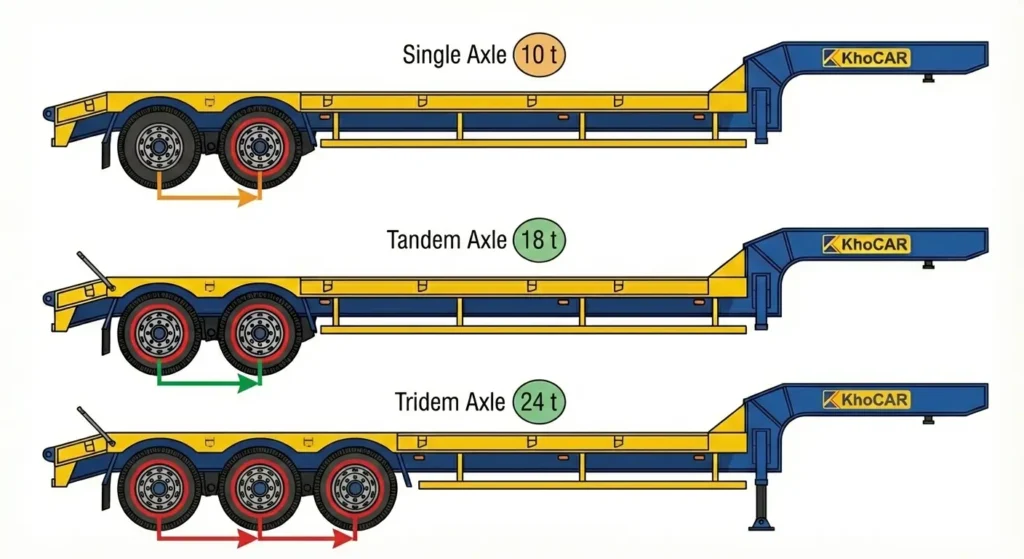

Lowbed Trailer Axle Load: Why It Matters More Than Total Weight

Many operators focus on total load capacity, but road authorities usually care more about

how that weight is distributed across the axles. This is where

lowbed trailer axle load becomes a critical factor in legal compliance and route approval.

In simple terms, axle load is the amount of weight carried by each axle or axle group. Even if your trailer is rated for heavy cargo, exceeding axle limits can still make your transport illegal.

What Is Axle Load and How Is It Calculated?

Axle load is calculated by dividing the total weight carried by a specific axle group.

However, real-world weight distribution depends on:

- Cargo position on the deck

- Suspension type

- Gooseneck load transfer

- Spacing between axles

That’s why professional operators measure axle loads using

weigh stations or portable axle scales, not just math on paper.

Typical Axle Load Limits (General Industry Ranges)

Legal axle limits vary by country, but most regulations fall within similar ranges:

| Axle Type |

Typical Legal Load Limit (Per Axle) |

| Single Axle |

8 – 10 tons |

| Tandem Axle (2 Axles) |

16 – 20 tons |

| Tridem Axle (3 Axles) |

24 – 30 tons |

Exceeding these limits often triggers:

- Mandatory permits

- Restricted routes

- Fines and offloading orders

So even if your trailer can

technically carry the load, axle laws may still say, “Nice try.”

How Axle Configuration Increases Legal Capacity

Lowbed trailers are available with different axle setups:

- 2 axles → lighter equipment

- 3–4 axles → medium-heavy machinery

- 5–7+ axles → heavy haul and oversized cargo

More axles mean:

- Lower weight per axle

- Better road compliance

- More approved routes

- Reduced pavement damage

This is why heavy-duty lowbed trailers often use

modular or hydraulic axle systems that can be added or removed based on the load.

Suspension Systems and Axle Load Control

Suspension plays a big role in how weight is shared between axles.

- Mechanical suspension: simpler, lower cost, but less adaptable to uneven loads

- Air or hydraulic suspension: better load equalization, safer for extreme weights, easier to fine-tune

Hydraulic suspension is especially useful when transporting:

- Tall equipment

- Uneven loads

- Sensitive industrial machinery

Because it keeps axle loads balanced even on uneven terrain.

Axle Load Affects Permits, Routes, and Costs

Higher axle loads often mean:

- Limited bridge crossings

- Mandatory route surveys

- Additional escort vehicles

- Higher permit fees

So, selecting the right axle configuration is not just about carrying the load; it’s about

moving it efficiently and legally.

How to Choose the Right Lowbed Trailer Specifications for Your Cargo

By now, it’s clear that no single specification works alone. Choosing the right lowbed trailer is about balancing

dimensions, deck height, load capacity, and axle load so the entire transport setup stays safe, legal, and efficient.

Here’s a simple way to think about it.

Step 1: Measure Cargo Dimensions First

Start with:

- Cargo length

- Cargo width

- Cargo height

Then match them to:

- Usable deck length

- Trailer width

- Deck height + legal road height limit

If the cargo is tall,

deck height becomes your top priority. If it’s long, you may need an

extendable lowbed trailer.

Step 2: Confirm Payload and GVWR Requirements

Next, calculate:

- Cargo weight

- Trailer tare weight

- Total combined weight

Make sure:

- Payload does not exceed trailer load capacity

- Total weight does not exceed GVWR

Always leave a small safety margin; equipment doesn’t like being pushed to its absolute limits, and neither do inspectors.

Step 3: Match Axle Configuration to Legal Limits

Then check:

- Number of axles

- Legal axle load per axle group

- Bridge and route classifications

For heavier machinery:

- More axles = lower axle load

- Lower axle load = fewer permits and route restrictions

This step often determines whether transport is smooth… or a paperwork marathon.

Step 4: Consider Route and Permit Complexity

Sometimes the “strongest” trailer is not the most efficient option.

Ask:

- Will oversize permits be required?

- Are there bridge or tunnel restrictions?

- Will escort vehicles be needed?

A slightly lower deck or additional axle can significantly reduce:

- Permit fees

- Planning time

- Delivery delays

Quick Reference: Matching Cargo to Trailer Type

| Cargo Type |

Key Requirement |

Recommended Lowbed Setup |

| Excavators & Loaders |

Moderate height & weight |

3–4 axle lowbed |

| Cranes & Tall Equipment |

Height compliance |

Low deck height + RGN |

| Transformers & Industrial Units |

Extreme weight |

5–7+ axle heavy-duty lowbed |

| Long Structures |

Length flexibility |

Extendable lowbed trailer |

Why Manufacturer Specifications Matter

Not all lowbed trailers are built the same, even if the axle count looks similar on paper.

Frame strength, suspension quality, and material thickness all affect:

- Real-world capacity

- Long-term durability

- Maintenance costs

That’s why working with experienced manufacturers like

KhoCAR helps operators get trailers designed for

actual working conditions, not just brochure numbers.

Need a Lowbed Trailer That Matches Your Exact Requirements?

Understanding specifications is the first step. Getting a trailer that’s actually built to meet those specifications is where real performance begins.

KhoCAR provides

custom-built lowbed trailers in the UAE, designed to match your exact load requirements, axle configurations, deck height needs, and legal compliance standards. Whether you transport construction machinery, industrial equipment, or oversized cargo, our engineering team ensures your trailer is built for real-world conditions, not just catalog numbers.

Explore KhoCAR’s Lowbed Trailer Solutions

FAQs

What is the typical deck height of a lowbed trailer?

Deck height on lowbed trailers is usually designed very low to maximize legal transport height. Standard lowbed deck heights typically range from

800 mm to 1,200 mm (approx. 0.8 – 1.2 m) above ground, depending on axle configuration and trailer design. Lower deck heights improve clearance for taller cargo under legal limits.

What are common load capacity ranges for lowbed trailers?

Lowbed trailer load capacities vary widely based on axle count and build quality. Typical payload ranges include

30 t – 100 t or more, depending on configuration: lighter models on 2–3 axles carry lower loads, while multi-axle heavy-duty versions can exceed 100 t for very heavy machinery.

How do I determine the right axle configuration for my load?

Axle configuration (2–8 axles) should be matched with your cargo weight and legal axle load limits. More axles reduce the

weight per axle, increasing compliance with road regulations and allowing heavier total loads without overloading a single axle group; for example, 5+ axles are used for 70 t + payloads.

Are there standard dimensions for lowbed trailers?

While customization is common, typical lowbed trailer widths are around

2.55 m to 3.0 m, and lengths range from

around 9 m up to 22 m or more, depending on model and extendable options. These dimensions ensure flexibility for a wide range of machinery sizes.

Can lowbed trailers be extended for longer cargo?

Yes,

extendable lowbed trailers can increase platform length to accommodate long loads. For example, extendable models can reach over

24 m total length with telescoping sections, while the closed length is typically around

16–17 m.

What affects the legal height limit of a loaded lowbed trailer?

Legal height limits vary by jurisdiction, but total height is calculated as:

deck height + cargo height + any support equipment. Low deck profiles help keep total height within common legal limits (around 4.0 – 4.5 m in many regions), reducing the need for oversize permits.

What role does suspension play in load handling?

Suspension type, mechanical, air, or hydraulic, impacts load comfort, axle load distribution, and ride stability.

Air or hydraulic suspensions help equalize load stress across axles and improve compliance with regulatory limits, especially in long-haul or heavy-payload applications.

How is payload capacity calculated on a lowbed trailer?

Payload capacity equals the difference between the trailer’s

Gross Vehicle Weight Rating (GVWR) and its

tare weight (empty trailer weight). Always check manufacturer GVWR figures and consider a safety buffer to comply with legal road weight limits.

Do I need oversize permits for wide or tall lowbed loads?

Yes, if your loaded width exceeds standard road limits (commonly 2.5 m in many regions) or if total height surpasses local maximum height rules, permits, and sometimes escort vehicles are required. Planning routes and specs in advance reduces delays.

What kinds of cargo are lowbed trailers most commonly used for?

Lowbed trailers are ideal for oversized, heavy, and tall equipment such as excavators, cranes, bulldozers, industrial machinery, and project cargo. Their low deck height and multi-axle support make them suitable for loads standard trailers cannot safely carry.

Understanding these standard dimensions helps logistics teams quickly assess whether a specific machine or cargo type can be transported safely and legally.

Understanding these standard dimensions helps logistics teams quickly assess whether a specific machine or cargo type can be transported safely and legally.

But in technical terms, there are two different weight limits you must understand to avoid costly (and very illegal) mistakes.

But in technical terms, there are two different weight limits you must understand to avoid costly (and very illegal) mistakes.

For example:

For example:

Understanding these standard dimensions helps logistics teams quickly assess whether a specific machine or cargo type can be transported safely and legally.

Understanding these standard dimensions helps logistics teams quickly assess whether a specific machine or cargo type can be transported safely and legally.

But in technical terms, there are two different weight limits you must understand to avoid costly (and very illegal) mistakes.

But in technical terms, there are two different weight limits you must understand to avoid costly (and very illegal) mistakes.

For example:

For example: